Pre Engineered House Plans: A Comprehensive Guide

Pre engineered house plans have revolutionized the construction industry, offering homeowners greater efficiency, cost-effectiveness, and design flexibility. In this comprehensive guide, we will delve into the essential aspects of pre engineered house plans, highlighting their benefits, design considerations, and construction process.

Benefits of Pre Engineered House Plans

Pre engineered house plans provide a multitude of advantages, including:

- Time efficiency: Prefabricated components are manufactured off-site, reducing construction time by up to 50% compared to traditional methods.

- Cost-effectiveness: Mass production and standardized designs significantly lower labor and material costs, making pre engineered homes more affordable.

- Environmental sustainability: Prefabricated construction minimizes waste and uses eco-friendly materials, promoting environmental conservation.

- Design flexibility: While pre engineered plans provide a range of pre-designed options, they also allow for customization, enabling homeowners to personalize their home designs.

- Quality assurance: Prefabricated components are factory-assembled under controlled conditions, ensuring consistent quality and durability.

Design Considerations for Pre Engineered House Plans

When selecting a pre engineered house plan, several design factors should be taken into account:

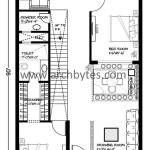

- Size and layout: Determine the size and layout of your desired home, considering the number of bedrooms, bathrooms, and living spaces required.

- Style and aesthetics: Choose a design that aligns with your architectural preferences, whether it's modern, traditional, or contemporary.

- Regional building codes: Ensure that the plan complies with local building codes and regulations, considering factors such as climate, seismic activity, and energy efficiency.

- Customization options: Explore the extent to which the plan allows for modifications and customizations to meet your specific needs and desires.

- Sustainability features: Consider energy-efficient appliances, solar panels, and other sustainable design elements to reduce your environmental impact and utility costs.

Construction Process for Pre Engineered House Plans

The construction process for pre engineered house plans involves the following steps:

- Site preparation: Prepare the building site by clearing the land, installing utilities, and establishing the foundation.

- Prefabrication: Prefabricated components are manufactured off-site in a controlled factory environment.

- Assembly: The prefabricated components are transported to the building site and assembled on the foundation using cranes or other heavy equipment.

- Finishing: The exterior and interior of the home are completed with finishes such as siding, roofing, paint, and flooring.

- Inspection: Final inspections are conducted to ensure the home meets building codes and the owner's specifications.

Conclusion

Pre engineered house plans offer a wide range of benefits for homeowners, including time efficiency, cost-effectiveness, environmental sustainability, design flexibility, and quality assurance. By carefully considering the design aspects and construction process, you can create a customized home that meets your unique needs and desires. With the advancements in pre engineered construction technology, it has become increasingly accessible for homeowners to build their dream homes with precision, efficiency, and affordability.

Detailed Civil Pre Engineered Steel Building Drawings

Pre Engineered Metal Building Details Options Simpson Steel

Some Typical Pre Engineered Steel Building S Detailed Drawings

Detailed Civil Pre Engineered Steel Building Drawings

Metal Building Floor Plan Design Designs

Detailed Civil Pre Engineered Steel Building Drawings

40 X 60 14 Steel Building For Ayden Nc 28513 Lth Structures

Morsalinsteeel

Raised Floor Over Crawl Space Engineered Plans And A Pool House Hansen Buildings

Modular Floor Plans Signature Building Systems