Commercial Greenhouse Construction Plans

Commercial greenhouse construction requires meticulous planning to ensure a productive and profitable operation. Developing comprehensive construction plans is crucial for outlining the project's scope, securing necessary permits, and guiding the construction process. This article explores the essential elements to consider when developing commercial greenhouse construction plans.

Site Selection and Analysis: The first step in planning a commercial greenhouse is selecting a suitable site. Factors such as sunlight exposure, topography, water availability and quality, accessibility, and proximity to markets and transportation infrastructure must be carefully evaluated. A thorough site analysis, often conducted by professionals, provides valuable information about soil composition, drainage, and potential environmental impacts. This data informs decisions regarding greenhouse orientation, foundation design, and utility connections.

Greenhouse Structure Type and Size: The choice of greenhouse structure depends on the intended crop, climate, and budget. Common types include hoop houses, gable greenhouses, gothic arch greenhouses, and Venlo greenhouses. Each type offers advantages and disadvantages regarding cost, durability, light transmission, and environmental control. Determining the appropriate size is crucial for optimizing growing space and ensuring efficient resource utilization. This requires careful consideration of projected crop yields, available space, and future expansion plans.

Framing and Covering Materials: Selecting appropriate framing and covering materials is essential for the structural integrity and performance of the greenhouse. Framing options include wood, galvanized steel, and aluminum, each offering varying levels of durability, cost, and maintenance requirements. Covering materials like polyethylene film, polycarbonate panels, and glass influence light transmission, insulation, and longevity. The chosen materials should align with the specific climate conditions, crop requirements, and budget constraints.

Environmental Control Systems: Maintaining optimal growing conditions within the greenhouse requires carefully planned environmental control systems. Heating, ventilation, and cooling systems are crucial for regulating temperature and humidity. Automated systems allow for precise control and efficient energy management. Considerations for these systems include energy efficiency, cost-effectiveness, and compatibility with the greenhouse structure and intended crops.

Irrigation and Fertigation Systems: Efficient and reliable irrigation and fertigation systems are essential for delivering water and nutrients to plants. Various irrigation methods, such as drip irrigation, flood irrigation, and ebb-and-flow systems, offer different levels of water efficiency and suitability for specific crops. Fertigation systems, which deliver nutrients through the irrigation system, ensure precise nutrient application and minimize waste. The choice of system should align with the specific crop requirements and water availability.

Electrical and Lighting Systems: Adequate electrical systems are necessary to power environmental control systems, irrigation pumps, and supplemental lighting. Supplemental lighting can extend the growing season or enhance growth during periods of low natural light. Careful planning of electrical layouts and load capacity is crucial for safe and efficient operation. Lighting choices, such as high-pressure sodium lamps, metal halide lamps, and LED grow lights, should be based on crop-specific light requirements and energy efficiency.

Benching and Flooring Systems: Benching systems provide elevated growing surfaces, improving drainage, airflow, and accessibility. Various benching materials, including metal, concrete, and plastic, offer different levels of durability and cost. Flooring materials should be durable, easy to clean, and provide good traction. Concrete, gravel, and specialized greenhouse flooring are common options. The choice of benching and flooring systems depends on the specific crop requirements, budget, and operational preferences.

Workflow and Logistics: Efficient workflow and logistics within the greenhouse are crucial for optimizing labor and minimizing operational costs. The layout of growing areas, walkways, and storage spaces should facilitate smooth movement of materials and personnel. Considerations for workflow optimization include accessibility for equipment, proximity to packing and shipping areas, and ergonomic design for worker comfort and safety.

Permitting and Regulations: Securing necessary permits and complying with local building codes and environmental regulations is a critical aspect of commercial greenhouse construction. Permitting requirements vary depending on location and greenhouse size. Consultation with local authorities is essential to ensure compliance with all applicable regulations.

Budgeting and Financing: Developing a detailed budget is essential for securing financing and managing project costs. A comprehensive budget should include costs associated with site preparation, materials, labor, equipment, and permits. Exploring financing options and securing funding before construction begins is crucial for ensuring project completion.

Project Management and Timeline: Effective project management is essential for ensuring the timely and efficient completion of the greenhouse construction project. Developing a realistic timeline, coordinating contractors and suppliers, and monitoring progress are key aspects of project management. Regular communication and collaboration between all stakeholders are essential for successful project execution.

Developing comprehensive commercial greenhouse construction plans requires careful consideration of numerous factors, from site selection and environmental control systems to permitting and budgeting. Thorough planning and attention to detail are crucial for creating a productive, efficient, and profitable greenhouse operation.

Ceres Schematic Design Bringing Your Commercial Greenhouse Facility From Idea To Reality Cans

Typical Design Of A Spanish Steel Greenhouse Extremely Resistant To Scientific Diagram

Quonset Style Greenhouse Plans Simplified Building

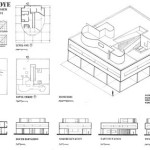

Construction Drawings

Greenhouse Floriculture Selecting And Building A Commercial Center For Agriculture Food The Environment At Umass Amherst

Bul235 Ae016 Florida Greenhouse Design

Greenhouse Floriculture Selecting And Building A Commercial Center For Agriculture Food The Environment At Umass Amherst

Research And Commercial Greenhouses Selection Guide Types Features S Globalspec

Greenhouse Structures Ornamental Ion

Commercial Greenhouse Structures Ggs