Honey Extraction House Plans: A Comprehensive Guide

Honey extraction, the process of removing honey from honeycombs, is a crucial step in beekeeping. The efficiency and hygiene of this process are significantly influenced by the design and functionality of the honey extraction house. This article provides a detailed guide to honey extraction house plans, covering essential design considerations, equipment requirements, and construction aspects.

Essential Considerations for Honey Extraction House Design

The design of a honey extraction house should prioritize efficiency, hygiene, and safety. The size of the house depends on the scale of the beekeeping operation, the amount of honey expected to be extracted annually, and the anticipated growth of the business. A small-scale hobbyist might require a simple, dedicated space, while a commercial operation will demand a larger, more sophisticated facility.

Ventilation is a critical factor for controlling humidity and preventing the growth of mold and bacteria. Proper ventilation also helps to remove the strong odors associated with honey. Natural ventilation, achieved through strategically placed windows and vents, can be supplemented with mechanical ventilation systems if necessary. Windows should be screened to prevent the entry of insects.

Adequate lighting is essential for visual inspection of the honey and equipment. Natural light is preferable, but artificial lighting should be installed to ensure sufficient illumination during all hours of operation. Consider using LED lighting, which is energy-efficient and provides bright, consistent light.

The layout of the extraction house should facilitate a smooth workflow, minimizing the distance that frames and honey need to be moved. A recommended layout typically includes areas for uncapping, extraction, filtering, and storage. This sequential arrangement helps prevent contamination and maximizes efficiency.

The floor should be made of a non-porous, easily cleanable material such as sealed concrete, epoxy, or stainless steel. Sloping the floor towards a drain facilitates cleaning and prevents the accumulation of liquids. Walls should also be constructed of smooth, washable materials like painted drywall or stainless steel paneling.

Temperature control is another important consideration. Maintaining a consistent temperature, ideally between 70-80°F (21-27°C), helps reduce the viscosity of the honey, making it easier to extract and filter. Insulation can help maintain a stable temperature, and heating or cooling systems may be necessary in regions with extreme climates.

Security is paramount. The extraction house should be designed to prevent unauthorized access, both to protect the honey and to ensure the safety of the equipment. Secure doors and windows, along with an alarm system, can deter theft and vandalism.

Key Equipment and Spatial Requirements

The equipment used in honey extraction needs specific space allocations within the overall floor plan. An uncapping station requires sufficient space for uncapping knives, uncapping tanks, and storage of capped frames. An electric heated knife or a specialized uncapping machine is often used to remove the wax caps from the honeycomb cells.

The honey extractor, a centrifugal machine that spins the frames to remove the honey, is a central piece of equipment. The size of the extractor depends on the number of frames it can hold. Radial extractors, which hold frames in a circular pattern, are generally more efficient for large-scale operations. Tangential extractors, which hold frames individually and require manual turning, are suitable for smaller operations. Sufficient space around the extractor is necessary for loading and unloading frames.

Filtering tanks are used to remove debris and impurities from the extracted honey. Multiple filters with progressively finer mesh sizes are typically used. Filtering tanks should be positioned at a height that allows for easy gravity flow into storage containers. Ample space is required for maneuvering around the tanks and accessing the filters for cleaning.

Storage containers for honey, such as food-grade buckets or drums, require a dedicated storage area. The size of this area depends on the volume of honey produced. Shelving or pallet racking can help maximize storage space and facilitate inventory management. The storage area should be kept clean, dry, and free from pests.

A honey pump may be used to move honey between tanks and containers, especially in larger operations. The pump should be food-grade and easy to clean. Space is required for the pump itself and for the hoses and connections.

A heated room or cabinet may be necessary to liquefy crystallized honey. This room should be well-insulated and equipped with a thermostat to maintain a consistent temperature. The size of the room depends on the quantity of honey that needs to be liquefied at one time.

Wash-up area is crucial. A dedicated sink with hot and cold running water is essential for cleaning equipment and personal hygiene. A dishwasher or other sanitizing equipment may be necessary for larger operations. Adequate counter space and storage for cleaning supplies are also required.

Construction Materials and Techniques

The selection of construction materials should prioritize durability, hygiene, and ease of maintenance. As previously mentioned, flooring should be non-porous and easy to clean. Sealed concrete, epoxy coatings, or stainless steel are good choices. Concrete should be properly cured before applying any coatings.

Walls should be constructed of smooth, washable materials. Painted drywall, stainless steel paneling, or fiberglass reinforced plastic (FRP) panels are suitable options. Seams and joints should be sealed to prevent the accumulation of dirt and moisture.

The roof should be well-insulated to help maintain a stable temperature. Metal roofing is durable and long-lasting, but it can be noisy during rain. Asphalt shingles are a more affordable option, but they may require more maintenance.

Plumbing should be installed according to local codes and regulations. Adequate drainage is essential for cleaning and sanitation. All plumbing fixtures should be made of food-grade materials.

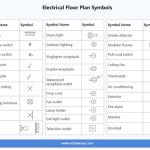

Electrical wiring should also be installed according to local codes and regulations. Adequate electrical outlets are needed for powering equipment. All electrical fixtures should be grounded and protected from moisture.

Consider the use of sustainable building materials and techniques. Using recycled materials, such as reclaimed wood or recycled metal, can reduce the environmental impact of the construction. Energy-efficient windows and insulation can help reduce energy consumption. Solar panels can be used to generate electricity.

Proper sealing and insulation are crucial for maintaining temperature control and preventing pest infestations. All cracks and crevices should be sealed with caulk or sealant. Insulation should be installed in the walls, roof, and floor to minimize heat loss or gain.

Consider building a separate small room for storing beekeeping equipment such as bee suits, smokers, and hive tools. This helps keep the extraction area separate and clean.

The design and construction of a honey extraction house require careful planning and attention to detail. By considering the factors outlined in this article, beekeepers can create a facility that is efficient, hygienic, and safe, ensuring the production of high-quality honey.

Mobile Honey House Bee Keeping

Building Our New Honey House Before Season Part 2

Cook Beals Floor Plans

Honey Extractor Free Woodworking Plan Com

Honey House Set Up Keeping Backyard Bees

A Re Imagined Honey Bee Research Centre

Honey Extraction Room Plans Layout

It S Time For A New Extractor And Maybe Honey House Bee Culture

Honey House Plans And Equipment Here It Is

Honey Sheds Extraction Design Build Farmbuild