Essential Aspects of Insulated Pump House Plans

Insulated pump houses are essential for protecting pumps and other equipment from the elements, especially in cold climates. When designing an insulated pump house, there are several key aspects to consider to ensure its effectiveness and longevity.

1. Insulation Type and Thickness

The type and thickness of insulation used in the pump house will determine its effectiveness in maintaining a stable temperature. Common insulation materials include fiberglass, cellulose, and spray foam. The thickness of the insulation will depend on the climate and the desired temperature range inside the pump house.

2. Ventilation

Proper ventilation is crucial for preventing condensation and moisture buildup inside the pump house. Ventilation openings should be placed at the top and bottom of the structure to allow for airflow. The size and number of ventilation openings will depend on the size of the pump house and the amount of equipment inside.

3. Moisture Control

In addition to ventilation, other measures should be taken to control moisture within the pump house. These measures include using vapor barriers, sealing all openings, and providing proper drainage around the structure. By controlling moisture, the risk of corrosion and damage to equipment is reduced.

4. Electrical Considerations

The electrical system in an insulated pump house must be designed to withstand the harsh conditions. This includes using waterproof electrical components, providing proper grounding, and protecting wiring from moisture and temperature fluctuations.

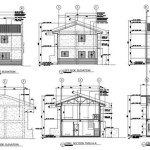

5. Structural Integrity

The pump house structure must be able to withstand the weight of the equipment, snow, and wind loads. The structure should be constructed using durable materials, such as concrete or steel, and should be properly anchored to the ground.

6. Accessibility

The pump house should be designed to allow for easy access to the equipment for maintenance and repairs. This includes providing adequate space around the equipment, as well as proper lighting and ventilation.

7. Aesthetics

While the primary purpose of an insulated pump house is to protect equipment, it can also be designed to be aesthetically pleasing. By using appropriate materials and finishes, the pump house can blend in with the surrounding environment or even enhance its appearance.

Conclusion

By considering these essential aspects when designing insulated pump house plans, you can ensure the effective protection of your pumps and equipment. A well-designed pump house will provide a controlled and insulated environment, preventing damage from the elements and extending the lifespan of your equipment.

Insulated Pump House

Free Insulated Pump House Plans

How To Design An Insulated Well Pump Cover

Precious Build Pump House 419759 Home Design Ideas Water Well Cover

Pump Houses Panelized Or Welded Steel Panel Built

Pump House Sheds Http Howardwatersystems Com Need 20to 20know Water Well Shed Plans

Pump Houses Panelized Or Welded Steel Panel Built

Insulated Well Houses And Sheds From M D Enterprises Outbuildingsok

How To Build A Pump House Shed Small Woodworking Projects Water Well Cover

Insulated Well Houses Outbuildingsok