Maple Syrup Sugar House Plans: Building Your Own Sugaring Operation

For generations, tapping maple trees and boiling sap into sweet syrup has been a cherished tradition in many parts of North America. The allure of a sugar house, with its fragrant steam and bubbling sap, offers more than just a tasty treat - it represents a connection to nature and a celebration of seasonal bounty. If you're considering venturing into the world of maple sugaring, building your own sugar house is an exciting project that can bring immense personal satisfaction and a unique source of natural sweetener. This article will walk you through the essential considerations for planning and designing your own maple syrup sugar house.

1. Determining Your Sugar House Size and Features

The first step in planning your sugar house is determining its size and layout. Consider these factors:

- Number of taps: The number of maple trees you plan to tap will dictate the capacity needed for your sugar house. A good rule of thumb is to allow 10 square feet of evaporator space for every 100 taps, providing enough room for processing the expected sap volume.

- Evaporator size: Evaporators come in various sizes, ranging from small household models to large commercial units. Choose an evaporator that aligns with your tapping capacity and desired production level. Consider factors like fuel type (wood, propane, or electric), and the evaporator's efficiency in terms of sap processing time.

- Storage space: Plan for ample storage space for your syrup, supplies, and tools. You'll need dedicated areas for syrup filtration, bottling, and labeling.

- Work area: Include a comfortable work area with a sturdy table and sufficient lighting for tasks such as filtering, bottling, and record-keeping.

- Amenities: Depending on your individual needs, consider adding amenities like a restroom, water supply, and a small kitchen area for preparing snacks or meals during long sugaring days.

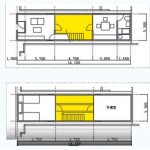

Once you have a clear understanding of your sugar house's purpose and size, you can start sketching a basic floor plan. This plan will serve as a guide for building your sugar house, ensuring that all essential components are accommodated and strategically positioned for efficiency and flow.

2. Choosing the Right Building Materials and Construction Methods

Your sugar house's construction will depend on your budget, skill level, and desired aesthetic. Some popular options include:

- Pre-fabricated kits: These kits offer a relatively quick and straightforward approach to building a sugar house. They typically include pre-cut wall panels, roof trusses, and other components, simplifying the construction process. However, pre-fabricated kits may limit customization options.

- Traditional wood framing: For those with carpentry skills and a desire for more control over design, traditional wood framing offers flexibility. You can choose from various wood species, customize the size and layout, and incorporate unique architectural elements.

- Metal buildings: Metal buildings are durable, low-maintenance, and offer a variety of sizes and configurations. They're often a cost-effective option, particularly for larger sugar houses.

- Other materials: While less common, you can also explore using other materials like concrete blocks, stone, or even recycled materials.

Regardless of the chosen materials, ensure that the construction adheres to local building codes and regulations. Consult with a building inspector or a qualified contractor for guidance on structural integrity, insulation, and ventilation requirements. Pay particular attention to fire safety measures, as the presence of an evaporator and open flames necessitates appropriate fire prevention and suppression systems.

3. Essential Equipment and Considerations

Beyond the building itself, equipping your sugar house with the right tools and equipment is crucial for efficient and successful sugaring operations. Key equipment includes:

- Evaporator: The heart of the sugar house, your evaporator transforms sap into syrup. Choose an evaporator that matches your tapping capacity and desired production level. Consider fuel type, efficiency, and ease of maintenance.

- Sap collection system: Prior to the sugar house, you'll need an efficient system for collecting sap from your trees. This typically involves using spouts, tubing, and a collection tank.

- Filtering equipment: After boiling, syrup needs to be filtered to remove any impurities or sediment. Choose filters suitable for your syrup volume and desired clarity.

- Bottling and labeling supplies: Once filtered, your maple syrup is ready for bottling. Choose attractive and functional bottles that meet all necessary food safety regulations. Invest in a labeling system that clearly identifies your product and its grade.

- Storage containers: Have adequate storage in place for your raw sap, finished syrup, and other supplies.

Remember that safety is paramount. Ensure you have fire extinguishers readily available and implement measures to prevent accidents. Proper ventilation is essential to avoid carbon monoxide buildup, especially when using wood-fired evaporators. It's also wise to have a first-aid kit on hand for any minor injuries that might occur.

By carefully planning, choosing the right materials and equipment, and prioritizing safety, you can create a sugar house that is both functional and enjoyable. With careful attention to detail, your sugar house can become a cherished part of your annual sugaring tradition, providing a delicious bounty and a rewarding connection to the natural world.

Building A Maple Sugar S Relatively Random

Building A Maple Sugar S Relatively Random

Outbuilding Plans Sugar House Plan Offers Workspace Kitchen And Storage 072b 0004 At Www Thegarageplan Com

Outbuilding Plans Sugar House Plan Offers Workspace Kitchen And Storage 072b 0004 At Www Thegarageplan Com

Sugar S 12 Steps With Pictures Instructables

Discover The Charm Of Sugar House Plans

24 36 Sugar S Plan Timber Frame Hq

24 36 Sugar S Plan Timber Frame Hq

Sugar S 12 Steps With Pictures Instructables

Pure Maple Syrup Sugar S Plans Craftsman House