Plans to Make a Pallet House

Building a house from repurposed shipping pallets has captured the imagination of many seeking affordable and eco-conscious housing solutions. While the aesthetic appeal and potential cost savings are alluring, careful planning and execution are crucial for a successful pallet house project. This article will explore important considerations and steps involved in planning a pallet house.

One of the initial steps is acquiring pallets. Not all pallets are suitable for construction. Pallets are often chemically treated for pest control, which can pose health risks. Heat-treated (HT) pallets are generally preferred for building projects due to their limited chemical treatment. It's essential to verify the pallet's markings and source to ensure they are safe for use. Sourcing enough pallets of consistent size and quality can be a significant undertaking, requiring connections with local businesses or pallet recyclers.

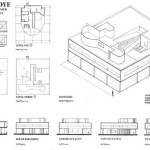

The design phase is crucial for any building project, and pallet houses are no exception. While the modular nature of pallets can simplify some aspects of design, it also presents constraints. Consider the desired size and layout of the house, including the number of rooms, window placement, and door locations. Software or sketching can aid in visualizing the final structure and ensuring the efficient use of pallets. Professional architectural advice may be beneficial, particularly when dealing with complex designs or local building codes.

Structural integrity is a primary concern when building with pallets. Pallets are designed for shipping, not structural support. Reinforcing the pallet structure is essential for creating a safe and stable house. This can involve adding supporting beams, using stronger connectors, and ensuring proper weight distribution. Consulting with a structural engineer is highly recommended to ensure the building meets safety standards and can withstand local climate conditions.

Insulation is critical for maintaining a comfortable living environment in a pallet house. Pallets, being primarily wood, offer some insulation, but additional measures are necessary for optimal thermal performance. Options include filling the voids between pallet boards with insulation materials like straw bales, recycled denim, or conventional insulation batts. Proper insulation also contributes to energy efficiency, reducing heating and cooling costs.

Exterior cladding plays a vital role in protecting the pallet structure from the elements. Options for cladding include traditional siding materials, such as wood, vinyl, or metal, as well as more unconventional choices like corrugated metal sheets or stucco. The choice of cladding depends on the desired aesthetic, budget, and local climate. Proper installation of the cladding is essential for preventing water damage and ensuring the longevity of the structure.

Roofing is another critical aspect of pallet house construction. The roof must be structurally sound to withstand wind, snow, and rain. Conventional roofing materials like asphalt shingles, metal roofing, or tiles can be used. The choice of roofing material should consider the overall design of the house, the local climate, and the budget. Proper installation is vital for preventing leaks and ensuring the structural integrity of the roof.

Interior finishing involves creating a comfortable and functional living space. Walls can be finished with drywall, plywood, or other materials. Flooring options include hardwood, laminate, or tile. Electrical wiring, plumbing, and HVAC systems must be installed according to local building codes and regulations. Careful planning and execution of these systems are crucial for safety and functionality.

Permitting and legal considerations are important aspects of any building project. Local building codes and zoning regulations vary, and it's essential to ensure the pallet house design complies with all applicable regulations. Obtaining the necessary permits before starting construction is crucial to avoid legal issues and potential demolition orders. Consulting with local authorities regarding building permits and regulations is strongly recommended.

Cost estimation is a critical step in planning a pallet house. While pallet houses are often touted as a low-cost housing option, the final cost can vary significantly depending on the size, design, and materials used. Factors contributing to the cost include pallet acquisition, foundation materials, insulation, cladding, roofing, interior finishing, and professional services like engineering and architectural consultation. Developing a detailed budget before starting construction can help avoid unexpected expenses.

Time management is essential for any construction project. Building a pallet house can be time-consuming, particularly if the builder is undertaking the project themselves. Factors influencing the construction timeline include the size and complexity of the design, the availability of materials, and the builder's skill level. Developing a realistic timeline and adhering to it can help ensure the project stays on track.

Sustainability is a key motivation for many considering pallet houses. Repurposing pallets reduces waste and minimizes the environmental impact of construction. However, it's important to consider the entire lifecycle of the materials used in the construction. Choosing sustainable materials for insulation, cladding, and roofing further enhances the eco-friendliness of the project. Proper disposal of construction waste is also crucial for minimizing environmental impact.

Construct Your Own House Tiny Pallet Plans 99 Pallets Como Construir Una Casa Casas Hechas Con Palets

How To Build A House Using Wooden Pallets Archdaily

The Pallet House I Beam

Pallet House Plans And Ideas Give New Life To Old Wooden Pallets

Knox Pallet House Inside Of Knoxville

Pallet House Schnetzer Andreas Claus Pils Gregor Archdaily

Diy Pallet House Plan

The Pallet House I Beam

Standard Pallet Size Build A House

Building A Pallet Playhouse